Turtleneck sweaters can be made from a variety of materials including wool, cotton, cashmere, and synthetic fibers. The manufacturing process generally involves the following steps:

Designing: The first step in manufacturing a turtleneck sweater is designing. This involves selecting the fabric, color, and style of the sweater.

Yarn selection: Once the design is finalized, the next step is selecting the yarn. Yarns can be spun from different fibers, and the choice of yarn can affect the texture and appearance of the sweater.

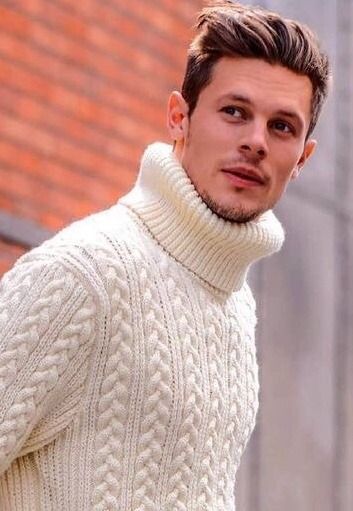

Knitting: The selected yarn is then knitted into the desired pattern and shape of the sweater using specialized machines. Knitting can be done in a variety of stitches, including ribbed, cable, and plain knit.

Cutting: After the knitting is completed, the sweater is cut into the desired shape and size using cutting machines.

Stitching: The cut pieces of the sweater are then sewn together using a sewing machine. The collar or turtleneck is typically knitted separately and then sewn onto the body of the sweater.

Finishing: Once the sweater is fully assembled, it goes through a finishing process. This can include washing, steaming, and pressing to give the sweater its final appearance and texture.

Quality Control: Finally, the sweater undergoes a thorough quality control check to ensure that it meets the required standards in terms of sizing, stitching, and overall quality.

Once the quality control process is complete, the turtleneck sweater is ready to be packaged and shipped